Managing Locations

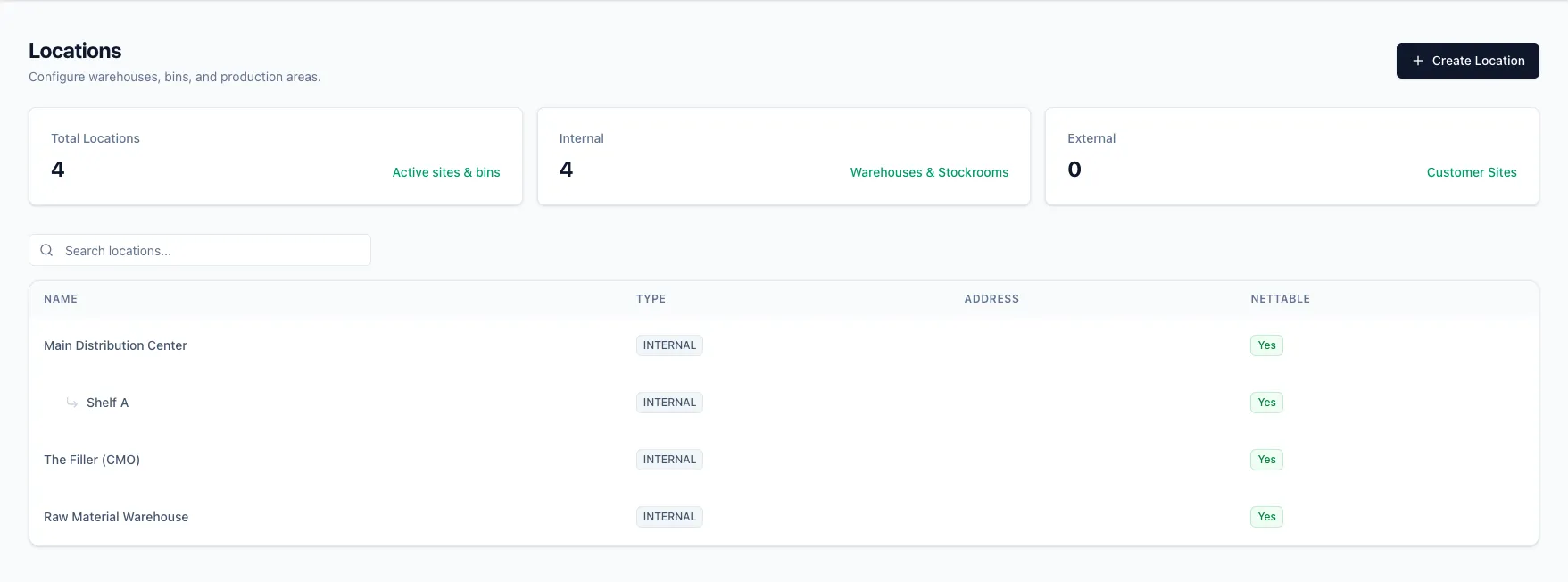

Whether you have a single workshop or multiple warehouses, Formul uses a Location Hierarchy to track exactly where your stock is.

Understanding Location Types

Section titled “Understanding Location Types”When creating a location, you must select a Type:

- INTERNAL: A location you own and control (e.g., “Main Warehouse”, “Freezer”).

- VENDOR: Represents stock held at a supplier (rarely used for on-hand tracking).

- CUSTOMER: Represents stock that has been shipped (often used for consignment).

- TRANSIT: Stock that is currently moving between locations.

Creating a Location Hierarchy

Section titled “Creating a Location Hierarchy”You can nest locations to create a precise map of your facility.

Example Structure:

- Main Warehouse (Root)

- Aisle 1 (Child of Main Warehouse)

- Shelf A (Child of Aisle 1)

- Aisle 2 (Child of Main Warehouse)

- Aisle 1 (Child of Main Warehouse)

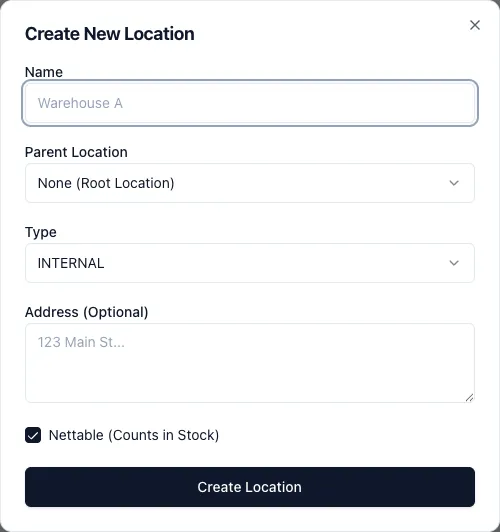

How to Create a Location

Section titled “How to Create a Location”-

Navigate to Inventory > Locations in the sidebar.

-

Click the Create Location button.

-

Name: Give it a descriptive name (e.g., “Shelf A”).

-

Parent Location:

- Leave as None (Root Location) for a top-level building or area.

- Select an existing location to nest this new one inside it.

-

Type: Usually

INTERNAL. -

Address: (Optional) Physical address, useful for top-level warehouses.

-

Nettable:

- Checked (Default): Stock in this location counts towards your total “Available” inventory.

- Unchecked: Stock here is ignored for availability (e.g., “Quarantine”, “Returns”, or “Damaged Goods”).

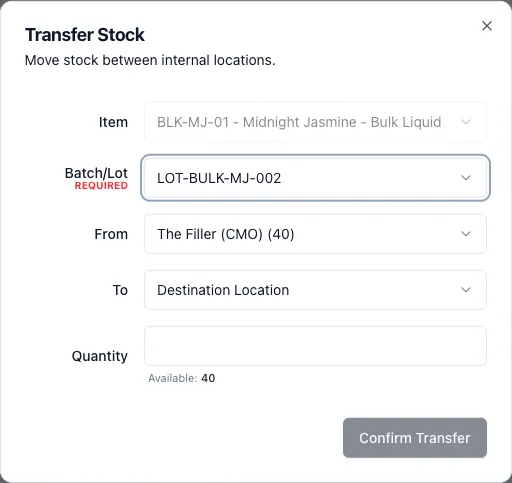

Moving Stock

Section titled “Moving Stock”To move items between locations (e.g., from “Receiving” to “Shelf A”):

-

Navigate to the Item Details page for the product you want to move.

-

Click the Transfer button.

-

Select the Batch you are moving (if applicable).

-

Choose the From and To locations.

-

Enter the Quantity to move.

-

Click Confirm Transfer.

Ready to see how stock changes over time? Check out Understanding the Inventory Ledger.