Work Orders

A Work Order (WO) is an instruction to your production team to make something. It tracks usage, costs, and output.

The Work Order Lifecycle

Section titled “The Work Order Lifecycle”| Status | Meaning | Inventory Impact |

|---|---|---|

| DRAFT | Initial plan. | None. |

| PLANNED | Scheduled for production. | None. |

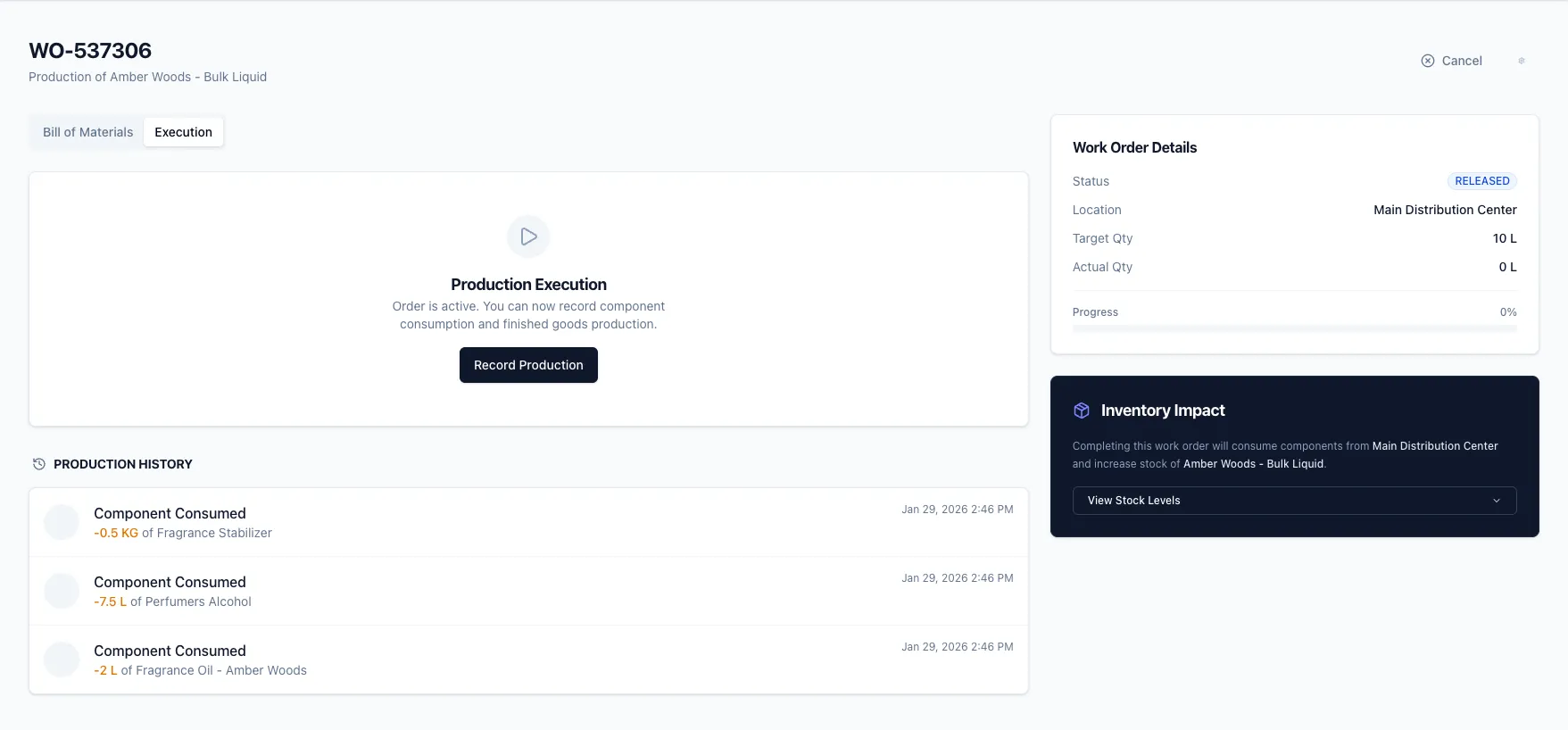

| RELEASED | Production has started. | Components are Allocated (Reserved). |

| COMPLETED | Production finished. | Components Consumed. Finished Goods Created. |

Executing a Work Order

Section titled “Executing a Work Order”-

Create: Click New Work Order, select the item and quantity.

-

Release: Click Release Order.

- Formul checks if you have enough stock.

- If successful, the components are reserved so no one else can use them.

-

Make: Physically produce the goods.

-

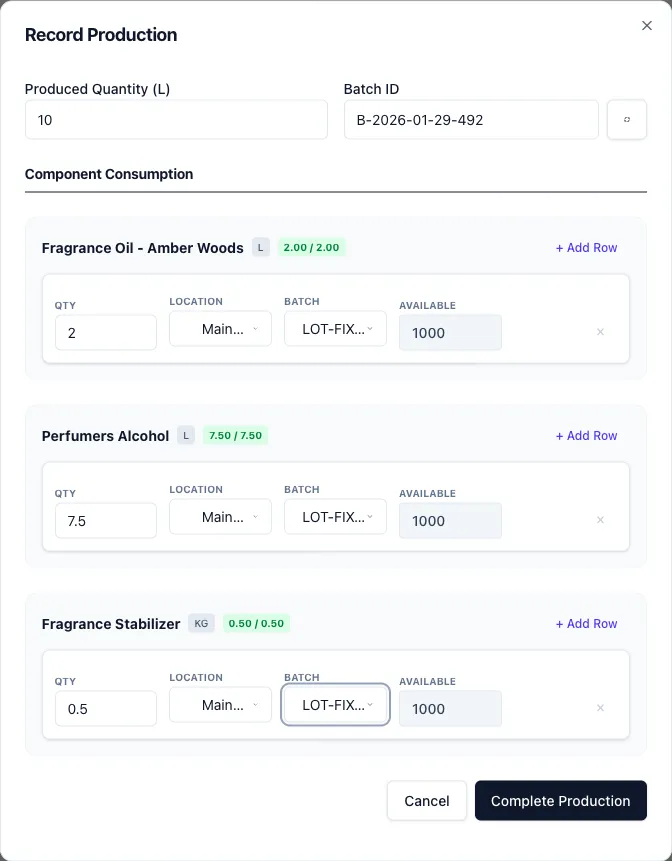

Complete: Click Record Production.

- Enter the actual quantity produced (e.g., you planned 100 but made 98).

- Assign Batch: Create a Lot Code for the finished product (e.g.,

LOT-2024-01). - Verify Consumption: Ensure the correct component batches are being used.

Handling Shortages

Section titled “Handling Shortages”If you try to Release a Work Order but don’t have enough ingredients:

- Formul will block the release (unless your account allows negative inventory).

- You need to Purchase or Produce the missing items first.