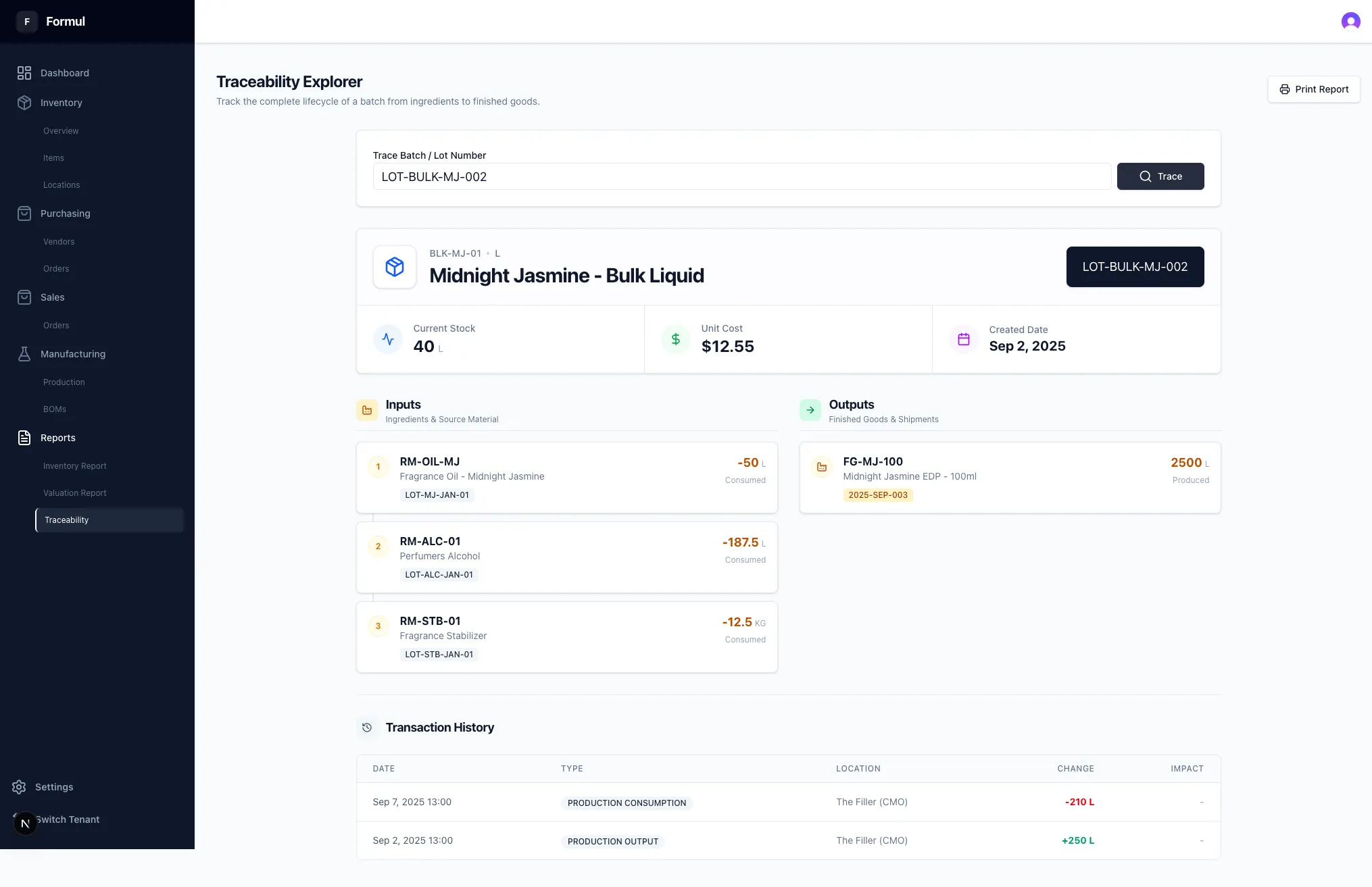

Traceability

Traceability is essential for quality control and recalls. Formul links every transaction, allowing you to trace a product’s history instantly.

The Traceability Report

Section titled “The Traceability Report”-

Navigate to Reports > Traceability.

-

Search: Enter a Batch ID or Lot Code (e.g.,

LOT-2024-001). -

Click Search.

Understanding the Genealogy Tree

Section titled “Understanding the Genealogy Tree”The report displays a split view showing the full history of the batch:

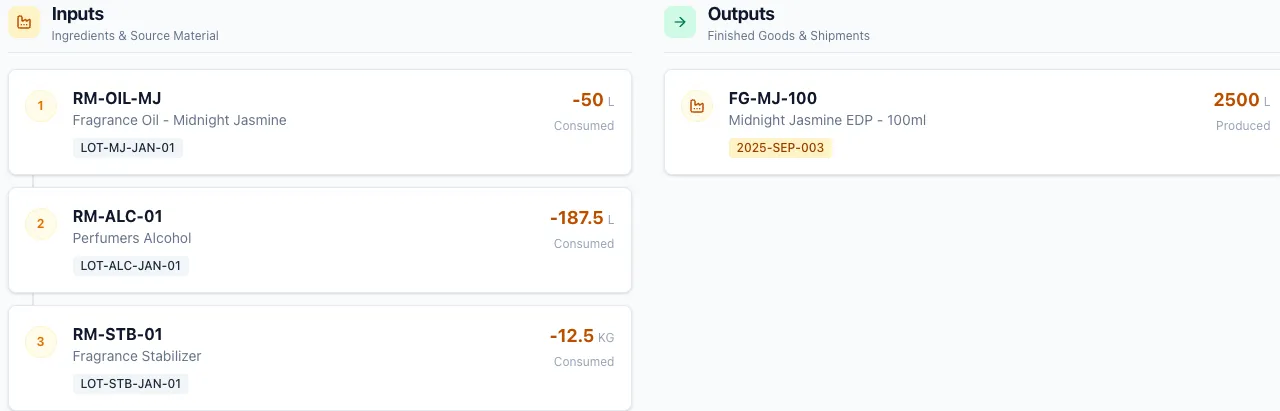

- Inputs: Shows the Ingredients & Source Materials that went into this batch.

- For a finished good, this lists the specific batches of raw materials used.

- Clicking a batch here traces it backward to see where it came from.

- Outputs: Shows Finished Goods & Shipments—where this batch went. The content depends on how the item was used:

- Used in Production: Shows the Finished Good and the specific Batch ID it was transformed into.

- Shipped to Customer: Shows the Customer Name and Sales Order #.

Use Case: Mock Recall

Section titled “Use Case: Mock Recall”If a vendor reports that “Ingredient X (Lot 123) is contaminated”:

- Search for

Lot 123in the Traceability Report. - Look at the Outputs column.

- If you see a Finished Good: Click the batch number to “step forward” and see who that finished good was sold to.

- If you see a Customer: You have identified the endpoint. Contact the customer immediately.